Synthetic roof underlayment is an advanced alternative to traditional materials like asphalt-saturated felt, offering superior durability, water resistance, and ease of installation. Engineered from high-performance polymers, synthetic underlayment is designed to enhance the longevity and performance of roofing systems, making it a preferred choice for modern construction and reroofing projects.

What is Synthetic Roof Underlayment?

Synthetic roof underlayment is a lightweight, durable, and water-resistant material installed between the roof deck and the external roofing material. Made from woven or spun polymers, it serves as a protective barrier that prevents water infiltration, resists tearing, and provides a strong foundation for the roof.

Features of Synthetic Roof Underlayment

- Material Composition:

- Made from polyethylene or polypropylene, creating a strong and flexible membrane.

- Water Resistance:

- Highly resistant to water, preventing leaks and moisture damage to the roof deck.

- Lightweight Design:

- Easier to handle and install compared to traditional felt underlayment.

- Durability:

- Resists tearing, UV degradation, and punctures, even under extreme conditions.

- Slip-Resistant Surface:

- Often features a textured surface to enhance safety during installation.

Benefits of Synthetic Roof Underlayment

- Superior Durability:

- Stronger and longer-lasting than felt, with resistance to tearing and weather-related wear.

- Lightweight and Easy to Install:

- Simplifies transportation and installation, reducing labor time and costs.

- Enhanced Weather Resistance:

- Performs well in extreme temperatures, heavy rain, and high winds.

- UV Protection:

- Can be exposed to sunlight for extended periods during construction without degrading.

- Compatibility:

- Works with various roofing materials, including asphalt shingles, metal panels, and tiles.

- Eco-Friendly Options:

- Many synthetic underlayments are recyclable, contributing to sustainable building practices.

Limitations of Synthetic Roof Underlayment

- Higher Initial Cost:

- More expensive than traditional felt underlayment, though offset by its longevity and performance.

- Specialized Installation:

- Requires proper training and techniques to ensure optimal adhesion and performance.

- Slipperiness:

- Can become slippery when wet, though many products include textured surfaces to address this issue.

Applications of Synthetic Roof Underlayment

- Residential Roofs:

- Commonly used under shingles, tiles, and metal roofing for enhanced protection.

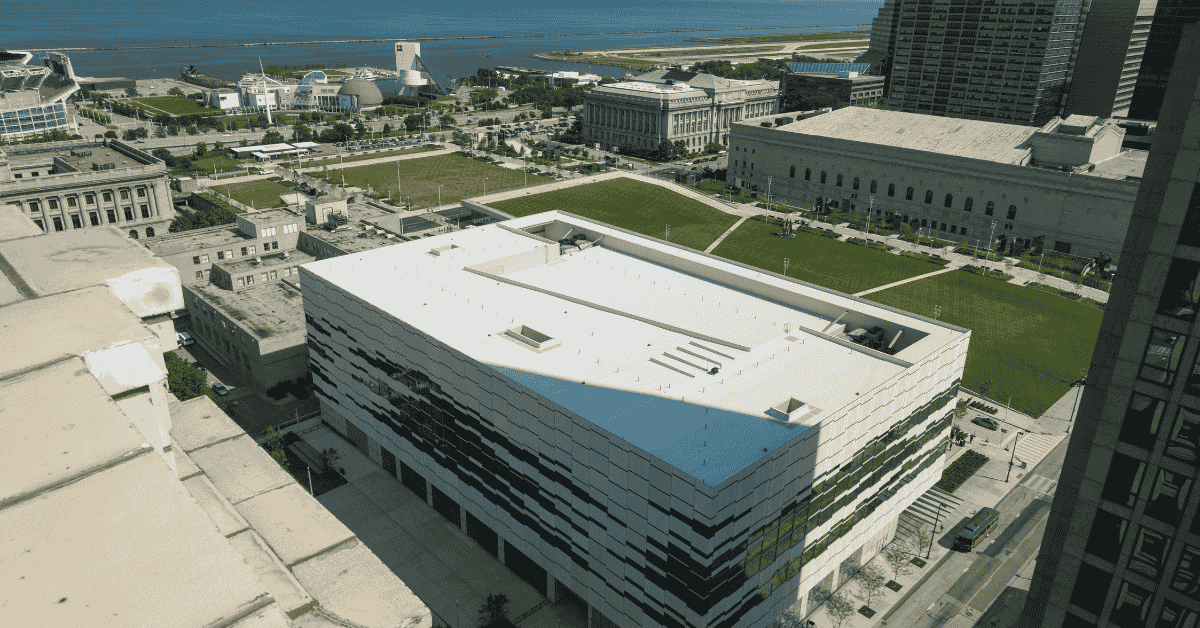

- Commercial Buildings:

- Ideal for flat or low-slope roofs requiring a durable, water-resistant barrier.

- Extreme Weather Regions:

- Performs exceptionally well in climates with heavy rain, snow, or high winds.

- New Construction and Reroofing:

- Suitable for both new builds and replacement roofing projects.

Installation Process

- Preparation:

- Ensure the roof deck is clean, dry, and free of debris.

- Unrolling the Material:

- Start at the eaves and roll out the underlayment horizontally, aligning it with the roof edge.

- Securing the Underlayment:

- Fasten using nails, staples, or compatible adhesives, following manufacturer recommendations.

- Overlapping Sections:

- Overlap rows by at least 4 inches to maintain a continuous protective barrier.

- Edge and Seam Treatment:

- Seal seams, valleys, and penetrations with compatible tape or sealants for additional waterproofing.

Maintenance Tips for Synthetic Underlayment

- Inspect After Installation:

- Check for wrinkles, tears, or improper fastening to ensure proper adhesion and performance.

- Replace During Reroofing:

- Synthetic underlayment should be replaced when installing new roofing material to maintain effectiveness.

- Protect During Construction:

- If left exposed for extended periods, inspect for UV or weather damage before applying the final roofing material.

- Ensure Proper Ventilation:

- Adequate attic ventilation reduces moisture buildup that could affect the underlayment.

Why Choose Synthetic Roof Underlayment?

Synthetic roof underlayment offers numerous advantages over traditional materials, including enhanced durability, water resistance, and ease of use. Its ability to withstand extreme weather conditions, UV exposure, and heavy loads makes it a reliable choice for modern roofing systems.

Conclusion

Synthetic roof underlayment is a superior choice for homeowners and contractors seeking a high-performance, long-lasting solution for protecting roofs. Its advanced design, ease of installation, and resistance to weather-related wear make it an excellent investment for any roofing project. Whether used in residential or commercial applications, synthetic underlayment ensures a strong, durable foundation for years to come.

-

What is Flat Roofing: EPDM, TPO, and Roll Roofing

Flat roofing is a popular choice for both residential and commercial buildings, offering a sleek design, affordability, and efficient use of space. Among the most widely used flat roof materials are EPDM, TPO, and roll roofing, each catering to specific needs and preferences. This guide provides an overview of these materials, highlighting their features, benefits,…

-

Essential Roof Decking Information for Homeowners

Roof decking, or roof sheathing, is a crucial component of your home’s roofing system, providing structural support and forming the foundation for roofing materials. Understanding its types, functions, and maintenance can help homeowners identify issues, protect their investment, and ensure a safe and energy-efficient home. This guide covers everything from common materials like plywood and…

-

Roofing Underlayment 101: Comparing Felt, Synthetic, and Ice & Water Shield

Roofing Underlayment 101: Roofing underlayment is an essential yet often overlooked part of roof anatomy, acting as a crucial layer of protection between the roof deck and the shingles. This guide explains the types of underlayment—felt, synthetic, and Ice & Water Shield—detailing each one’s features, advantages, and limitations to help homeowners and roofers make informed…